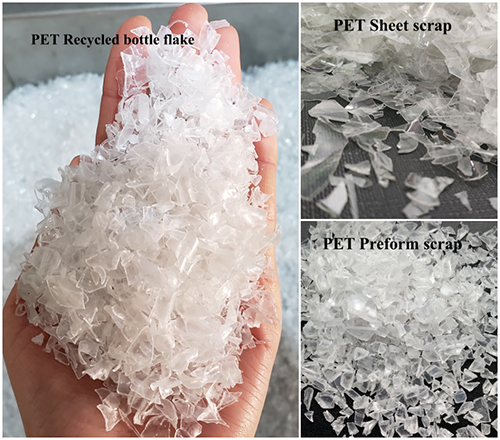

| Raw Material | PET Recycled flake/ PET sheet scrap/PET Preform scrap |  |

| Using Machine | LDHW-600*1000 |  |

| Drying& Crystallized Temperature set | 180-200℃Can be adjustable by property of rawmaterial | |

| Crystallized time set | 20mins | |

| Final material | Crystallized and Dried PET scraps and final moisture can be about 30ppm |  |

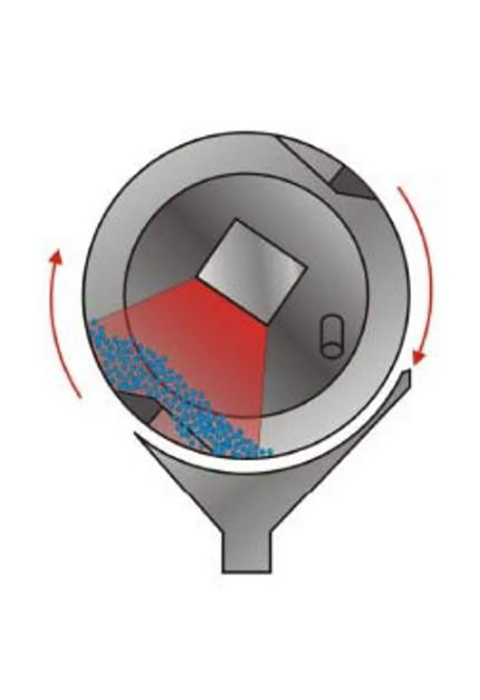

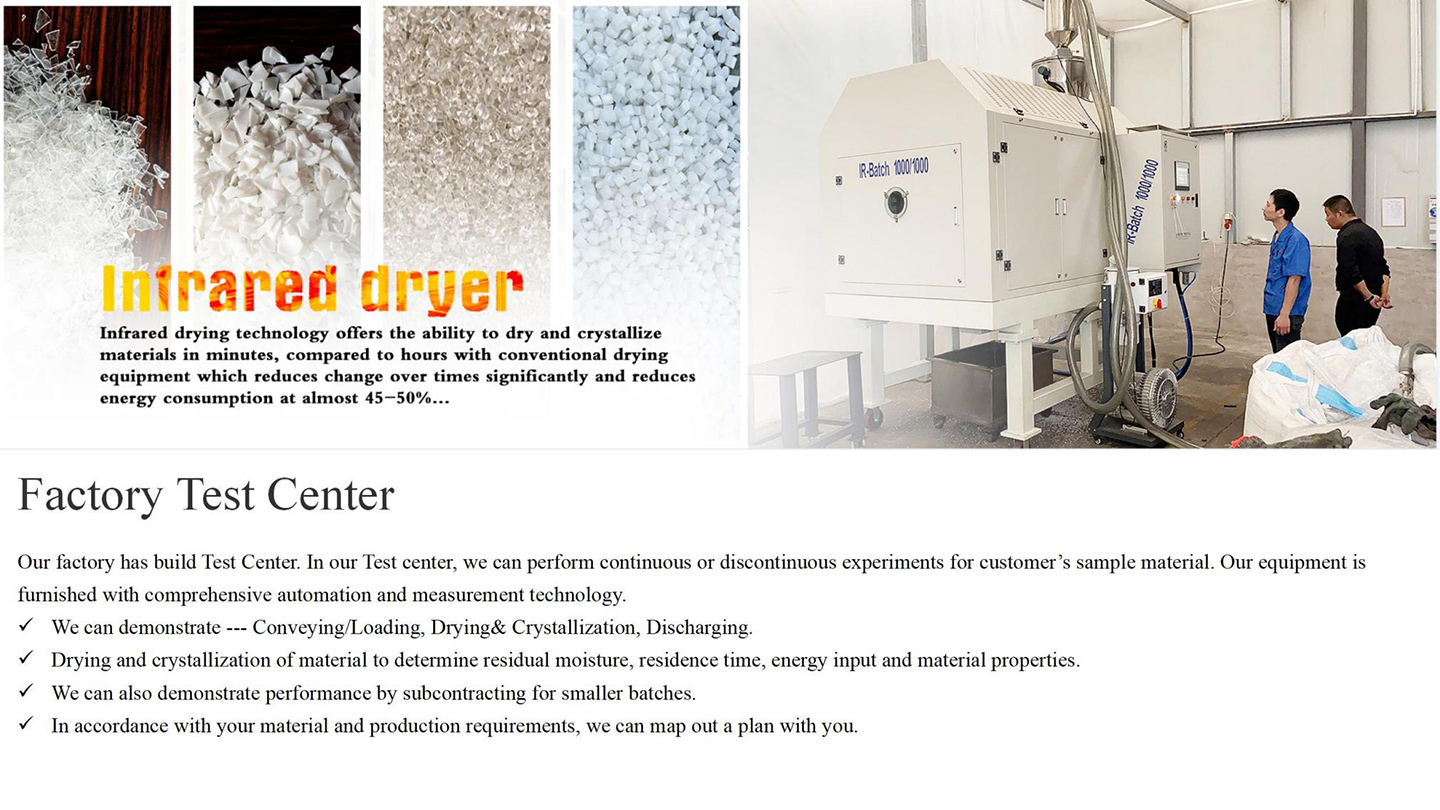

>> Supply Experienced engineer to your factory to help installation and material test running >> Adopt aviation plug, no need to connect the electrical wire while the customer get the machine in his factory. To simplify the installation step >> Supply the operation video for installation and running guide >>Support on line service Normally the PET Bottle flakes or sheet scrap with initial moisture level of up to 10000-13000ppm. The PET Bottle flakes or sheet scrap (Virgin or mixed ) will be recrystallized in Infrared crystal dryer in 20mins, the drying temperature will be 150-180℃ and dried to 50-70ppm,then fed to Single screw extruding system for further processing

>> Supply Experienced engineer to your factory to help installation and material test running >> Adopt aviation plug, no need to connect the electrical wire while the customer get the machine in his factory. To simplify the installation step >> Supply the operation video for installation and running guide >>Support on line service Normally the PET Bottle flakes or sheet scrap with initial moisture level of up to 10000-13000ppm. The PET Bottle flakes or sheet scrap (Virgin or mixed ) will be recrystallized in Infrared crystal dryer in 20mins, the drying temperature will be 150-180℃ and dried to 50-70ppm,then fed to Single screw extruding system for further processing ● Limiting the hydrolytic degradation of the viscosity. ● Prevent increasing AA levels for materials with food contact ● Increasing the capacity of the production line up to 50% ● Improvement and make the product quality stable-- Equal and repeatable input moisture content of the material

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation.

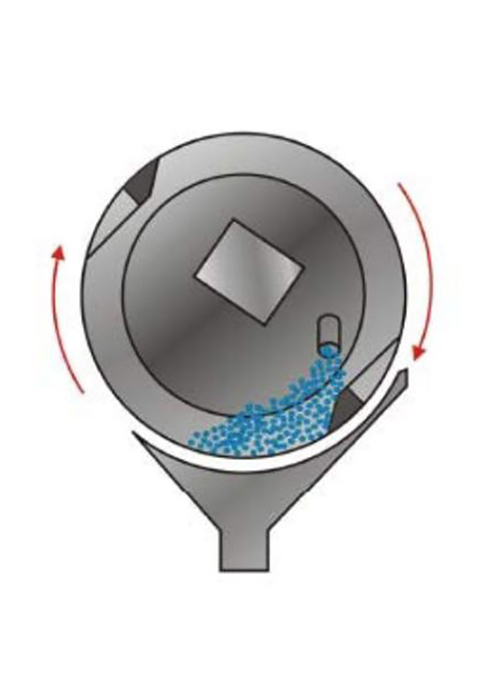

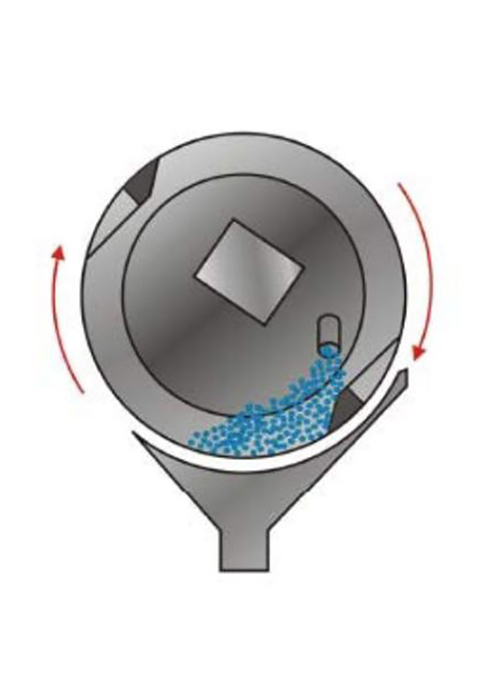

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation. ● Instant start-up and quicker shut down ● Uniform crystallization ● No pellets clumping & stick ● Carefully material treatment ● Up to 60% less energy consumption than conventional drying system ● No segregation of products with different bulk densities ● Independent temperature and drying time set ● Easy clean and change material

● Instant start-up and quicker shut down ● Uniform crystallization ● No pellets clumping & stick ● Carefully material treatment ● Up to 60% less energy consumption than conventional drying system ● No segregation of products with different bulk densities ● Independent temperature and drying time set ● Easy clean and change material| Item | IRD Dryer | Conventional Dryer |

| Transfer medium | None | Hot air |

| Heat transfer | Both inside & outside particles together. | From outside to inside particle gradually. |

| Energy | Save at least 20~50% energy compared to traditional dryer. | Consume much energy. |

| Process time | 1. Crystallization & drying: They are processed simultaneously within about 8~15 minutes. 2. Drying and crystallization at a time | 1. Crystallization: About 30~60 minutes. 2. Drying: About 4~6 hours. |

| Moisturecontent | 1. Under 50-70 PPM after IRD processed. | 1. Spend 30~60 minutes to change amorphous PET to crystallized PET first. 2. Under 200PPM after about 4 hours dehumidifier processed. 3. Under 50 PPM after about more than 6 hours dehumidifier processed. |

| Lead time | 20mins | More than 6 hours. |

| Material changeover | 1. Easy & faster. 2. There are only 1~1.5 times capacity of material hourly consumption in the buffer hopper. | 1. Difficult & slowly. 2. There are 5~7 times capacity of material hourly consumption in the crystallizer & hopper. |

| Operation | Simple--- By Siemens PLC control | It is difficult such as it must put a little crystallized PET in the crystallizer when beginning operation. |

| Maintenance | 1. Simple. 2. Lower maintenance cost. | 1. Difficult. 2. Higher maintenance cost. |